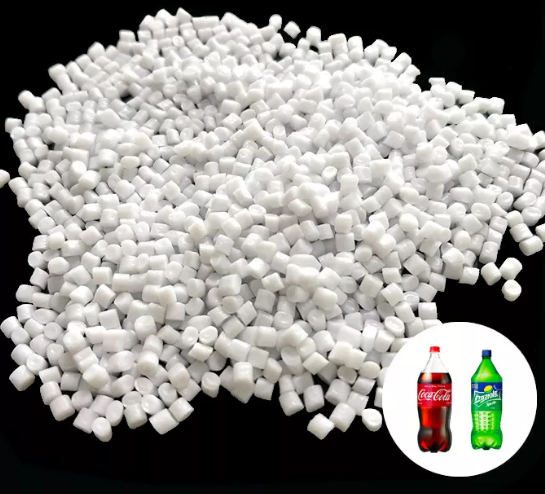

100% Virgin Food Grade Sinopec PET Resin for Raw Materials

sinopec pet resin

PET plastic is Polyethylene terephthalate : referred to as PET or PETP. Poly-terephthalic acid-based plastic, mainly including polyethylene terephthalate PET and polybutylene terephthalate PBT. Polyethylene terephthalate also known as polyester resin. It is a condensate of terephthalic acid and ethylene glycol, together with PBT, referred to as thermoplastic polyester, or saturated polyester.

PET Characteristic: is milky white or light yellow highly crystalline polymer, the surface smooth and shiny.

Anti-fatigue, good abrasion resistance, small wear and high hardness, with the maximum toughness of thermoplastic; electrical insulation performance, affected by temperature, but poor resistance to corona. Non-toxic, weatherability, anti-chemicals, good stability, high moisture absorption, drying before molding is necessary. Weak acid and organic solvents, but not hot water immersion, not alkali.

PET Plastic Molding processing: Can be injection molding, extrusion, blow molding, coating, bonding, machining, plating, vacuum metallization, printing.

PET resin Specification

| Parameter | Unit | Specification | Specification |

| Intrinsic Viscosity | dL/g | 0.80±0.02 | 0.84 |

| Crystallinity | % | ≤60 | ≤60 |

| Content of COOH | Mol/t | ≤26 | ≤26 |

| Content of acetaldehyde | ppm | ≤1.0 | ≤1.0 |

| Color Value

L B |

— — |

≥83 ≤1.0 |

≥83 ≤1.0 |

| Dust Content | ppm | ≤100 | ≤100 |

| Melting point | °C | 243±2 | 243±2 |

| Wt. of 100 chips | g | 1.55±0.10 | 1.55±0.10 |